Projects

Custom 3D Printer Enclosure

Designed and built a custom, sound proofing/protective enclosure for my Ender 3 Pro using 3 x IKEA Lack tables, 3D printed parts, and misc. hardware. STLs and instructions made publicly available via Thingiverse.com (linked below).

View Project

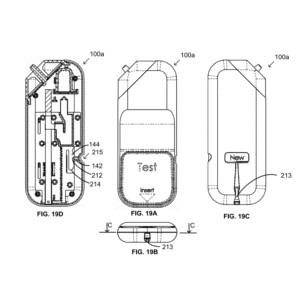

Fully Integrated POC Ferritin Blood Test

Designed, iterated on, injection molded, tested, and patented for use with the Amina POC reader. Made to automatically run a lateral flow assay, and display the results to a battery-powered analyzer (optionally) connected to a smartphone.

View Patent

VR-Sculpted Candle Holder with Forest Spirits

Designed custom using Oculus Medium (VR sculpting app) and my 3D printer as a gift. Features kodama spirits from Princess Mononoke, complete with spring-loaded bobbling heads.

View Project

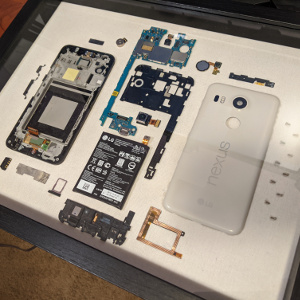

Nexus 5x Teardown

Disassembled, mounted, and framed the parts of a (dead) Nexus 5x as a gift to the person who originally lent it to me.

View Project

Project Squaterloo

A low cost, retrofit device with multiple modules developed to assist weightlifters of all skill levels with limited ankle mobility. Final design uses interlocking plates of variable thickness, machined out of aluminum and ABS.

Made in a team of 4 for our University of Waterloo ME 2017 Capstone Project.

T-Rex Planter

Made during a 2 week quarantine at a friend's house using air dry Sculpey, internally supported with galvanized steel wire, and given several coats of spray on waterproofing.

View Project

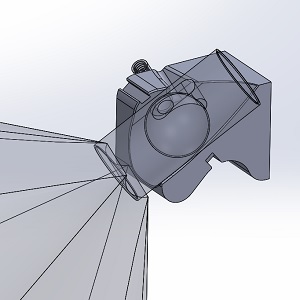

Custom Optimal VR Sensor Mounts

3D printed external sensor mounts for an Oculus Rift to provide secure holding and optimal tracking coverage over a defined play space.

View Project

Planck Keyboard Build

A custom build of an open source mechanical (specifically "Planck") keyboard. For a more elegant look, I used thin acrylic to hold the keys, and a CNC router on the base.

View Project

Magic Mirror on a Budget

A Raspberry Pi-powered Magic Mirror made as a Christmas gift for my sister on a tight budget. Designed around an old stripped down monitor, with hidden light strips on both sides.

View Project

Lasercut Water Droplet Automata

Lasercut this custom version of an idea I'd seen online out of clear and black acrylic as a gift to my Mom. When you turn the crank, the rings mimic the ripple of a water droplet.

Low Poly Pug Art

An artpiece made as a gift for my brother one Christmas. This is a 'low poly' rendition of our late pug Saru, lasercut out of MDF, coloured with acrylic paint, and glued in place.

View Project

Custom C++ Software for Laser Projection Setups

Self-taught C++ between projects, and developed a complex, thorough app for field technicians to correctly install laser screen shaker arrays.

Made while working at Christie Digital.

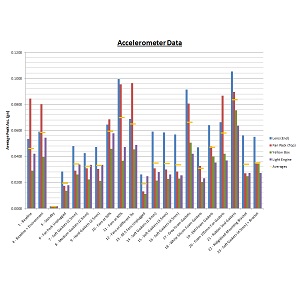

Cinema Projector Shaky Image Investigation

A start-to-finish investigation of visible vibration on Christie's most popular cinema projectors. Solved with accelerometers, high speed video, custom tests & analysis software, prototyping, and implementation.

Made while working at Christie Digital.

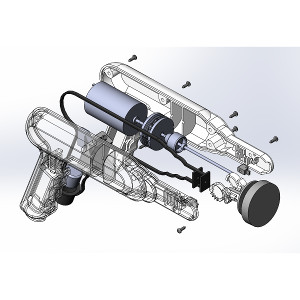

SCRUBR - Squeeky Clean Rapid Universal Buildup Remover

A mechanical (as specified by the project requirements) dish cleaning tool with a motorized, geared, clutched, flexible, scrubbing head, and a magnetic handle. Built in a team of 6 as a 3rd year design project.

View ProjectTropical Steel Wax Melter

A custom machined/welded wax melter made for my mom for Mother's Day. The leaves and hammock were plasma cut and manually formed, and the trunks and base were turned on a lathe. The beach was shaped with an angle grinder.

View ProjectMore Projects Coming Soon!

Projects section still under construction...